The primary piles or king piles of combined walls can also be used as bearing piles.

Combi wall sheet pile.

Combined wall systems are used when regular sheet piles are not strong enough to carry the required loads.

Hammer steel sells and rents the most efficient combi wall systems for added strength for applications including river cofferdams bridge pier protection foundations and levee construction.

Rr large diameter piles can be built into a continuous combi wall by welding interlocking sections or complete sheet piles into them.

The connector is the third component and is welded to or interlocked with the king pile and connects the king pile to.

Combined walls built up with box piles or hz m or steel tubes and standard sheet piles are one of these solutions.

And can bear high vertical loads e g.

The high modulus components known as king piles can be tubular box bearing or other types of fabricated piles.

Tubular piles are the main retaining elements of the combined wall king piles carrying horizontal loads from soil and water pressures and vertical loads from the superstructure or anchoring system the intermediary az sheet piles infill sheets transfer the horizontal loads from the retained soil and water to the.

Combined walls with steel tubes are an alternative to the hz m az system.

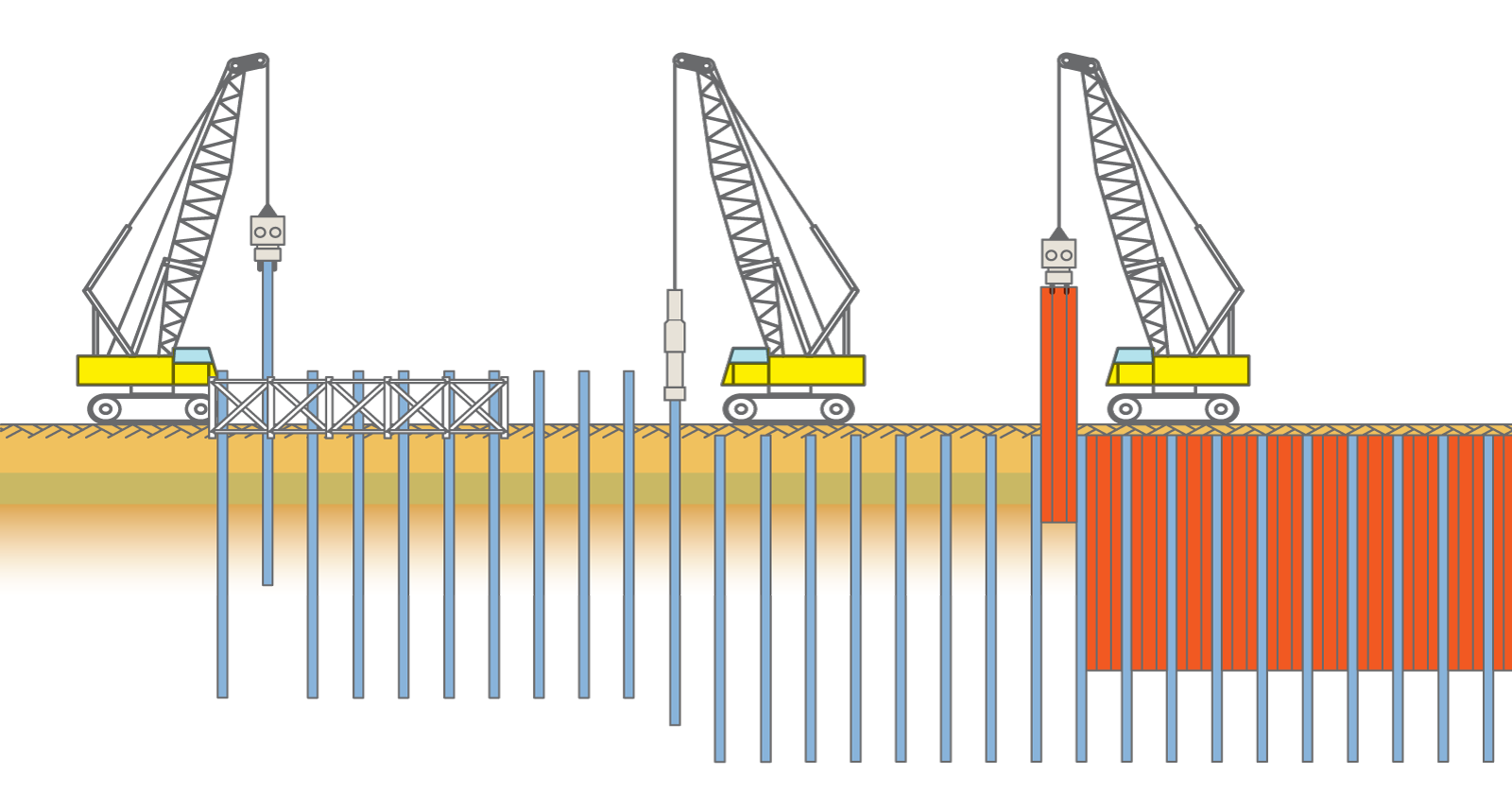

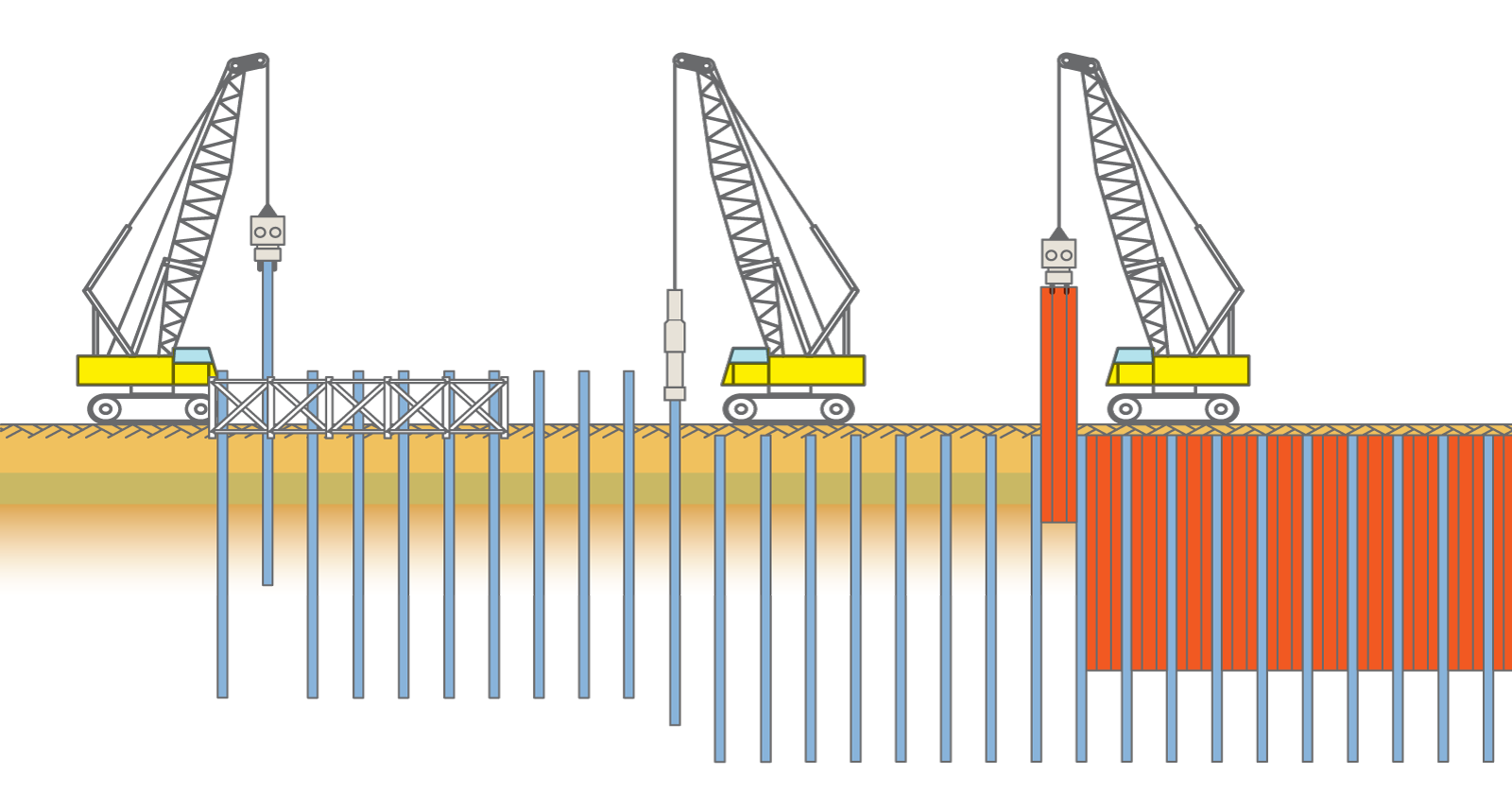

It is essential that a stable heavy adequately rigid and straight pile driving template frame adapted to.

In a combi wall piles act as the load bearing.

Combi wall systems also known as combined wall systems are formed by using beams and steel sheet piles.

Combi walls are piling walls that are comprised of high modulus structural components interspaced by lighter sheet piles.

Steel sheet piles can easily be combined to form special arrangements and create systems with large bending resistance.

The two main components of a combined wall system are the king pile hzm or pipe and a pair of intermediary sheet piles.