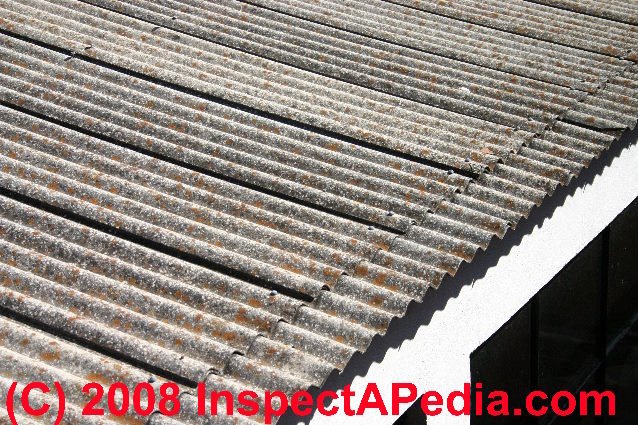

Corrugated asbestos cement sheets were applied in the same way that corrugated iron was applied either nailed to wooden strips bolted to the.

Corrugated asbestos cement sheets percentage.

Fibrous cement created an easy and affordable alternative to corrugated metal panels which offer little insulation and inevitably rust over time.

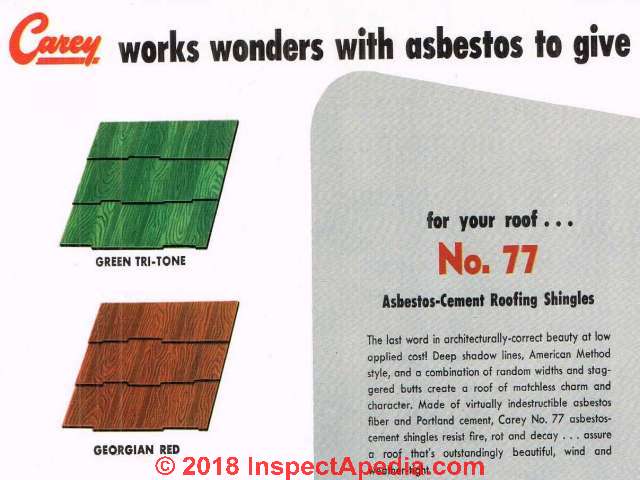

Adding asbestos to the cement made the corrugated roofing sheets more heat resistant weatherproof and durable.

Asbestos cement genericized as fibro or fibrolite short for fibrous or fibre cement sheet and ac sheet is a building material in which asbestos fibres are used to reinforce thin rigid cement sheets.

Since the cement sheets were fireproof manufacturers initially considered them safer as compared to wood.

Corrugated roofing sheets made of asbestos is common in uk homes constructed prior to 2000.

With the advent of asbestos cement corrugated sheets the enclosure of factory buildings warehouses and train sheds was simple economical and effective for either permanent or portable structures.

Corrugated asbestos sheets were used in the roofing and siding of all types of buildings especially in factories and farms.

The sheets are laid on the purlins and other roof members as indicated in the working drawings or as instructed by the engineer.

The maximum spacing of purlins under the sheets shall be 1 40 m for 6 mm thick sheets and should not exceed in any case.