What are the components of an advanced planning and scheduling system.

Describe the major components of an advanced planning and scheduling system.

Initial post should be at least 250 words and apa format.

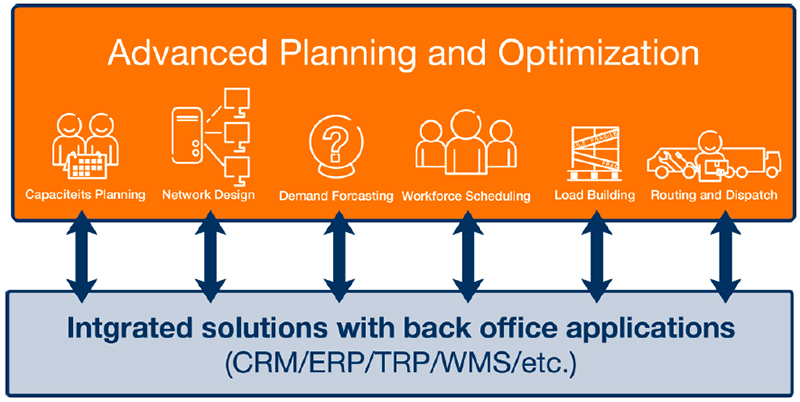

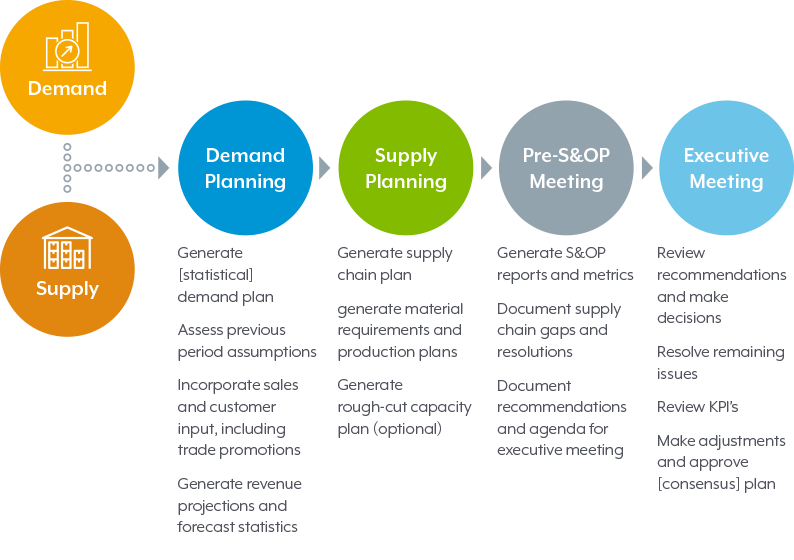

Advanced planning system aps system this is a network which includes plants warehouses and customers and transportation flows.

Describe the major components of an advanced planning and scheduling system.

In this process the best util view the full answer.

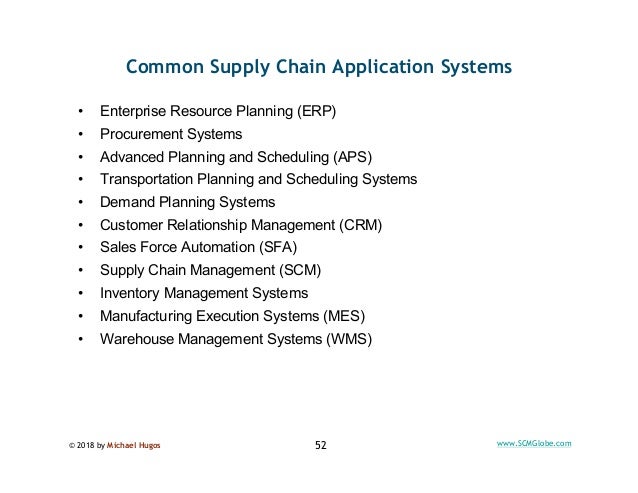

Advanced planning and scheduling aps is a type of system that tracks costs based on the activities that are responsible for driving costs in the production of manufactured goods.

Advanced planning and scheduling aps also known as advanced manufacturing refers to a manufacturing management process by which raw materials and production capacity are optimally allocated to meet demand.

While there are many conceptual approaches to designing supply chain planning applications like aps.

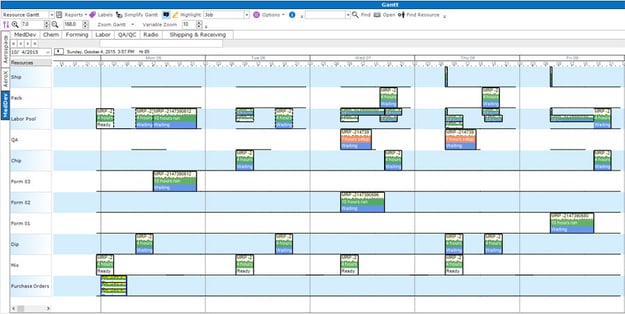

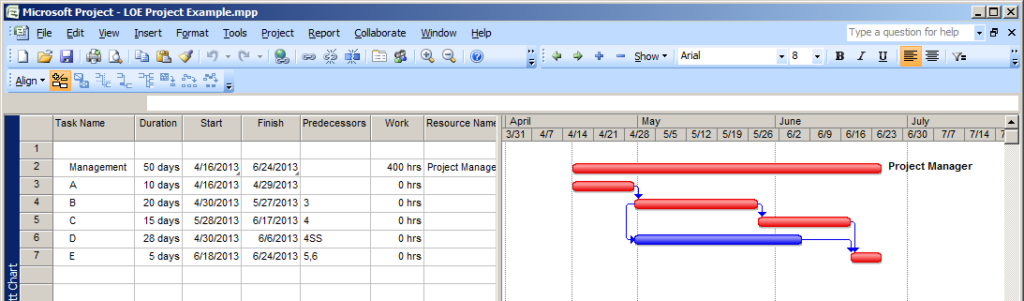

Production control ensures that production team can achieve required production target optimum utilization of resources quality management and cost savings.

Production planning is required for scheduling dispatch inspection quality management inventory management supply management and equipment management.

Describe the major components of an advanced planning and scheduling system.

Initial post should be at least 250 words and apa format please use this in write up.

An aps allocates raw materials and production capacity optimally to balance demand and plant capacity.

What are the major challenges in implementing such a system.

What are the major challenges in implementing such a system.

Aps is especially well suited to environments where simpler planning methods cannot adequately address complex trade offs between competing priorities.

Describe the major components of an advanced planning and scheduling system.

Advanced planning and scheduling system aps also called as manufacturing management process.

Aps describes any computer program that uses advanced mathematical algorithms or logic to perform optimization or simulation on finite capacity scheduling sourcing capital planning resource planning.

The components are demand management resource management resource optimization and resource allocation.

It is the process by which raw material are converted into finished goods.

What are the major challenges in implementing such a system.